PROCESSING

Tests and measurements

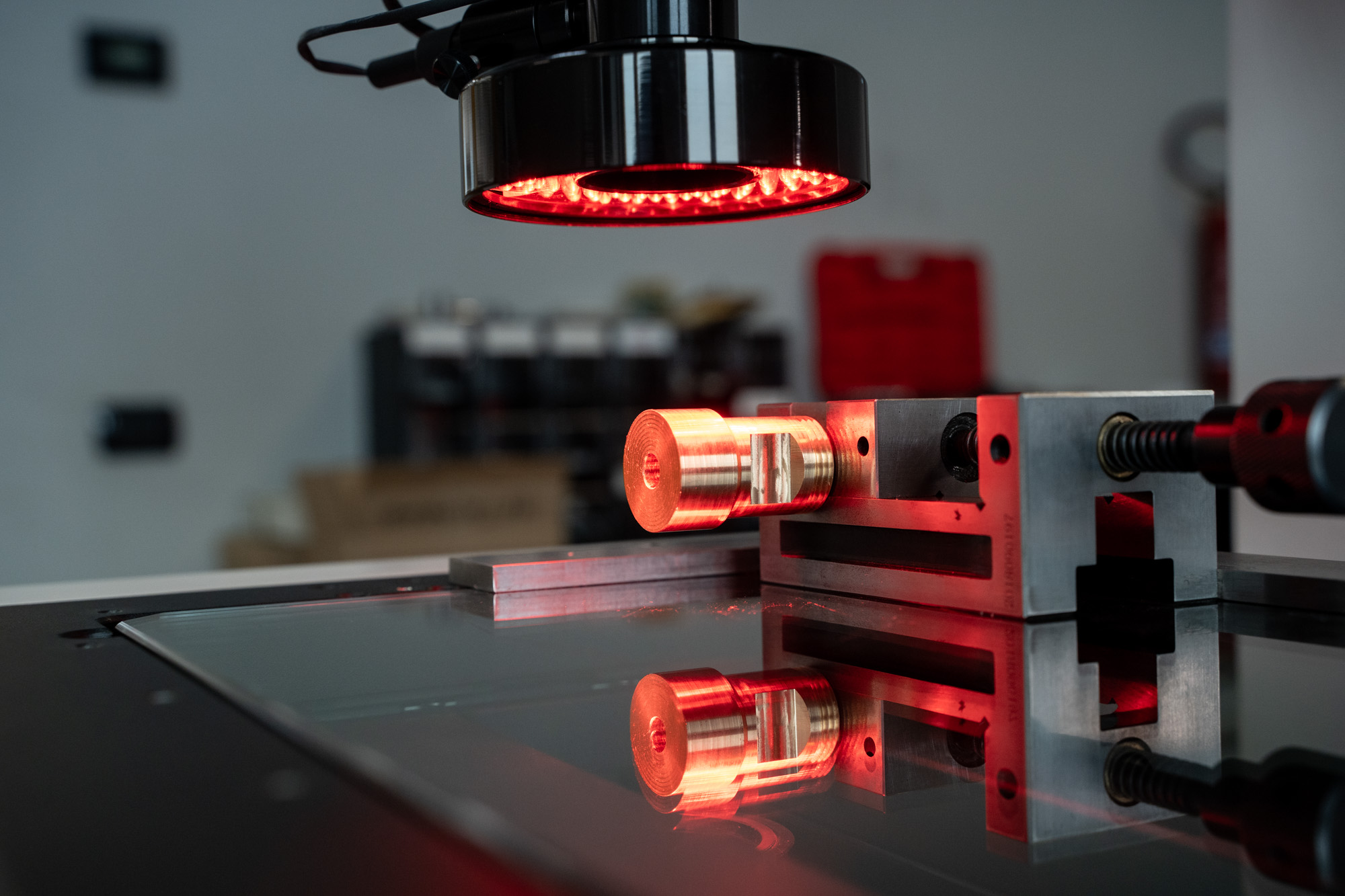

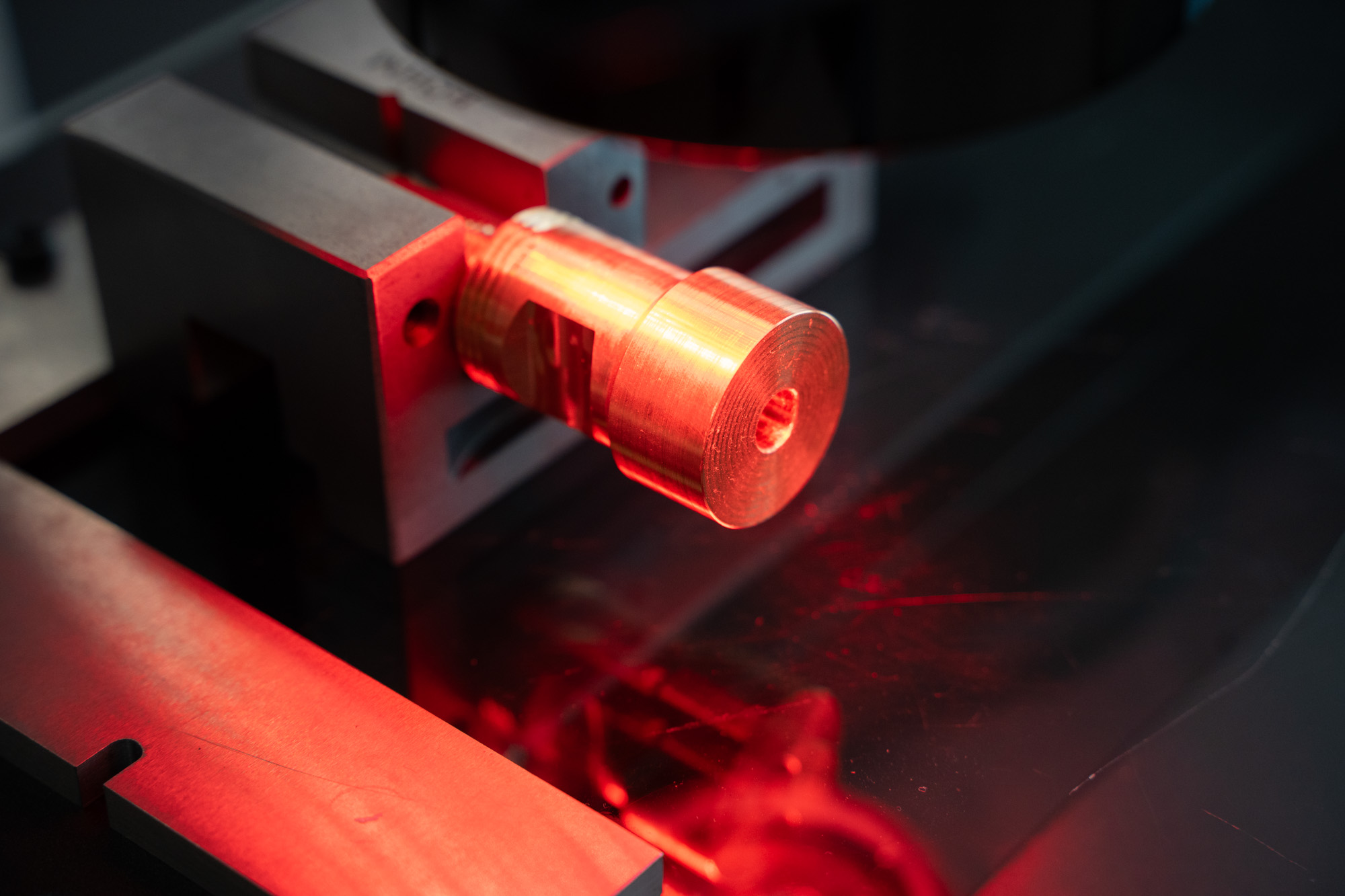

Internal quality control: advanced instrumentation for high standards

We carry out all tests and measurements in-house to meet the strict dimensional and surface quality standards required by an increasingly attentive and demanding market. Our certified tools are constantly monitored to ensure maximum precision and reliability.

In addition to standard equipment such as gauges, micrometers and plug gauges, we have state-of-the-art machinery, including

3D CMM (Coordinate Measuring Machine): for precise three-dimensional measurements.

Profile projectors: for detailed analysis of contours and shapes.

Hardness testers: to measure materials hardness.

SO2 atmosphere corrosion test chambers: to assess materials corrosion resistance.

Electrolysis cells: for advanced electrochemical analysis.

Galvanic thickness measurement equipment: to precisely check the thickness of galvanic coatings.

This range of advanced tools allows us to guarantee compliance with the highest quality standards, ensuring products that meet our customers’ specific requirements and maintaining strict control over every stage of the production process.