WHAT WE DO

Complete stamping and turning services

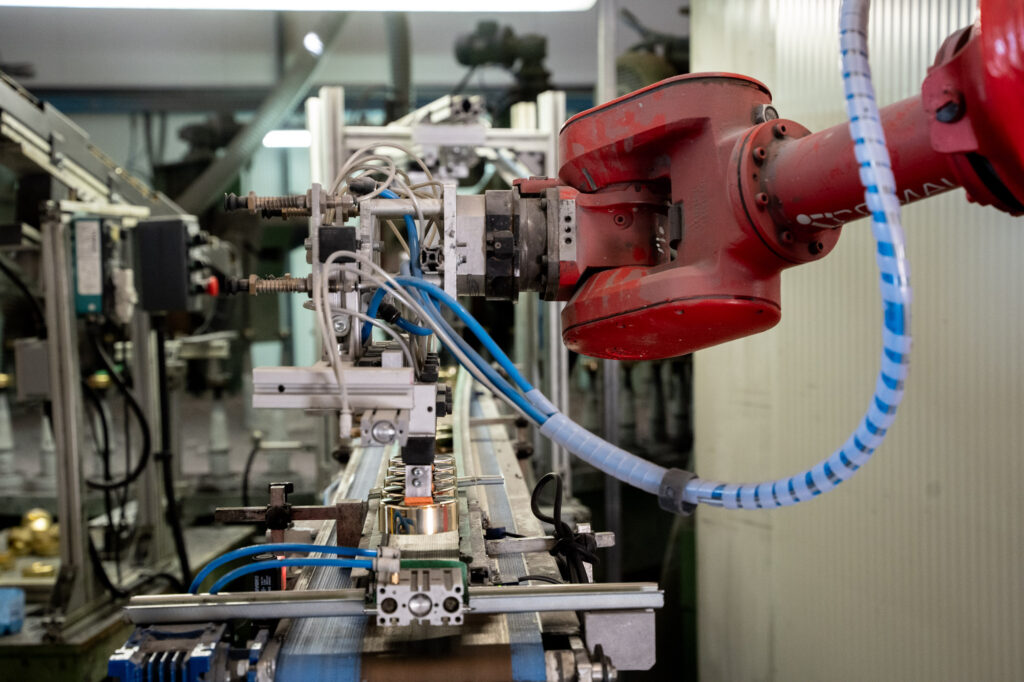

We are constantly investing in advanced technologies to improve our production processes. Automation is a key element of our approach, allowing us to increase productivity and reduce errors. Our production lines are equipped with state-of-the-art machines, enabling us to offer high quality products efficiently.

Our Commitment

Technology and automation

We are constantly investing in advanced technologies to improve our production processes. Automation is a key element of our approach, allowing us to increase productivity and reduce errors. Our production lines are equipped with state-of-the-art machines, enabling us to offer high quality products efficiently.

Quality controls

We offer complete stamping, turning, polishing and chrome plating services, using advanced technology and strict quality control.

Flexibility and customisation

As a partner, we guarantee a careful and helpful collaboration, supporting you with innovative solutions and certifications of excellence at every stage of the project.

Sustainability

As a partner, we guarantee an attentive and helpful collaboration, supporting you with innovative solutions and certifications of excellence at every stage of the project.

Processing areas

Taps

Handles

Valves

Hydraulic accessories

Quality and

machines

Quality

Quality is at the core of our business. All procedures at Metalbrass are managed according to EN ISO 9001:2015, and our care for the environment is certified by EN ISO 14001:2015. Furthermore, our NSF/ANSI 51 certification guarantees the quality of our chrome plating for the food & beverage industry.

Tools

We carry out strict production checks to ensure that our cold and hot forged components, as well as components turned from brass bar, meet the highest dimensional standards. We use advanced measuring tools managed by the SAM-ERP2 programme, and have a measuring room equipped with precision machines such as the Mitutoyo Crysta-Plus M574, a RUPAC machine and a hardness tester. We also have a 3D printer for prototyping.

Tests

In the chromium plating department, we use the FISHERSCOPE X-RAY XDL-B to check the electroplating coating thickness, and we perform adhesion and thickness tests, surface quality control, Kesternich Test and salt spray tests to ensure that each product meets the highest quality standards.

Products

We produce different types of components, including cold and hot forged and turned parts. Each type is manufactured with the utmost care and precision, using high-quality materials and advanced production processes.